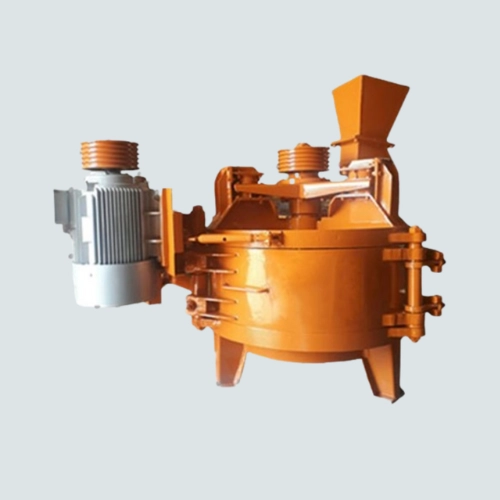

Overview

Sand makers, also known as sand-making machines, are essential in industries that require finely crushed sand for construction and manufacturing. These machines are specifically designed to produce artificial sand and fine aggregates by crushing hard materials such as rocks and minerals. Sand makers are indispensable in industries such as construction, concrete production, and infrastructure development.

Price and Feature Comparison of the Rabbit Sand Maker with Other Sand Makers

Compared to other sand-making machines like the “Rock and Rock” and the double-deck sand makers, the Rabbit Sand Maker is more affordable. This makes it an ideal choice for new mine owners with limited budgets for setting up equipment. Due to its reasonable price, the Rabbit Sand Maker is widely bought and sold in the market. However, one of its main differences from other sand makers is its lower production capacity. In contrast, double-deck sand makers offer greater upgrade potential and higher capacity, and they can be built in various sizes.

Different models of the Rabbit Sand Maker are typically divided into two types: thick shaft (T800) and thin shaft. The thick shaft model, which is more commonly used, has a body thickness of 20 millimeters, while the thin shaft model has a body thickness of 15 millimeters. Therefore, when buying or selling this machine, it is important to consider the shaft type and body thickness to ensure that the machine chosen meets your specific needs.